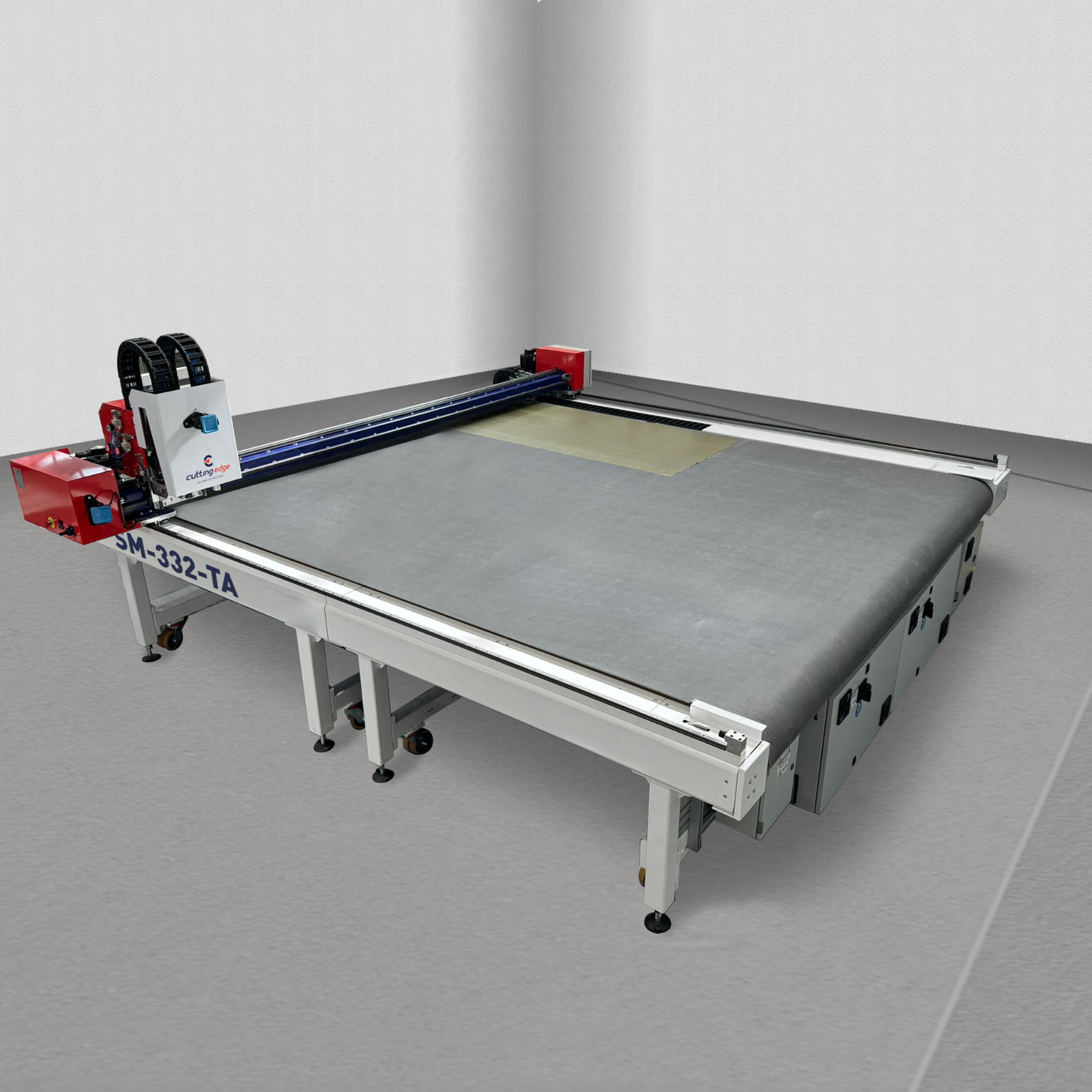

SM-332-TA

Digital Cutting Plotter with Conveyor Belt

The Ultimate Machine for Continuous Cutting

The SM-332-TA is a state-of-the-art cutting machine designed for technical fabrics and composite materials.

With high operating speed, it increases productivity without compromising cutting accuracy. Its integration with automation systems makes it ideal for high-volume industrial production environments.

ADVANTAGES OF THE SM-100-CA

- Optimized efficiency: Ensures a continuous workflow with minimal material waste.

- Versatility in materials: Compatible with a wide range of technical fabrics and composite materials.

- Industry 4.0 integration: Enables real-time monitoring and streamlined production management.

- Ease of use: Intuitive interface for quick operator learning.

- Simplified maintenance: Modular components allow for fast servicing and reduced downtime.

Advanced Technology & Intuitive Control

Equipped with dedicated CAD/CAM software, the SM-332-TA enables the precise cutting of complex patterns.

The Easy Production Management System (EPMS) ensures seamless Industry 4.0 integration, optimizing digital workflows and enhancing production efficiency.

High Performance & Guaranteed Reliability

The SM-332-TA is built for durability and top-tier performance.

Its high-quality materials and precise assembly ensure long-term operational reliability while minimizing maintenance costs.

Every component is designed to withstand wear and tear, even in intensive production environments.

Thanks to rigorous quality control and meticulous attention to detail, the SM-332-TA stands out as one of the most reliable solutions on the market.

Technical Specifications

Tools & Accessories

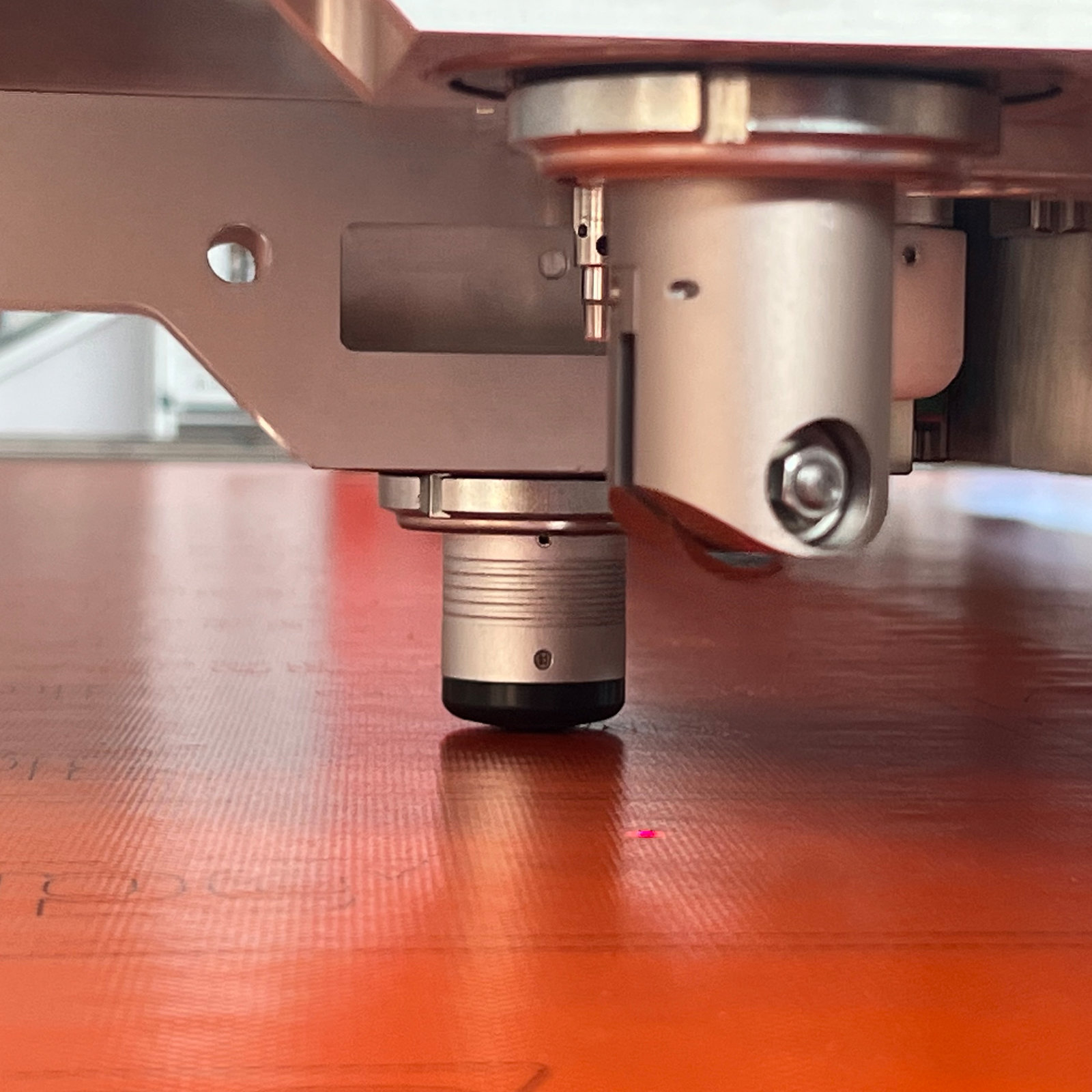

- Drag knife

- Oscillating knife

- Non-motorized rotary blade

- Motorized rotary blade

- Kiss-cut

- V-cut knife

- Oscillating V-cut knife

- Milling head

- Punching tool

- Creasing tool

- Ultrasonic blade

- Marker pen

- Laser pointer to determine the dynamic zero point

- Vacuum turbine for work top

- Industrial conveyor belt

- Motorized unwinding system for jumbo rolls with edge control

- Router for long distance diagnosis, technical assistance and installation of upgrades

Technical specifications and configurations

- Available in various sizes Extension modules for the safe unloading on cut out patterns

- Cutting speed up to 90 m/min

- Acceleration up to 1G

- Precision +/- 0,1 mm

- Repeatability +/- 0,05 mm

- Twin tool hubs

- Up to 4 different vacuum areas

Software

- EasyWork Xtreme

- Automatic nesting

- Splitbox

- Barcode reading

- Easy Production Management System (EPMS)

- Easy Awning Maker

- Easy Data Monitoring System

Applications

Composites

Packaging

Banners

Windreak barriers

Tension structures

Truck sides and roofs

Pool covers

Pergolas

Conveyor belts

Industrial doors

Roller blinds

Leather

Composites

Packaging

Banners

Windreak barriers

Tension structures

Truck sides and roofs

Pool covers

Pergolas

Customize the machine

Configurations

Nome della configurazione

Maecenas a lectus. In hac habitasse platea dictumst. Suspendisse id massa. Nullam porta velit sed lacus. Duis eleifend, felis eu euismod lacinia, felis erat feugiat nisl, vitae congue leo velit a massa. Quisque nec justo a turpis posuere tristique.

- Maecenas condimentum tincidunt lorem. Vestibulum vel tellus. Sed vulputate. Morbi massa nunc, convallis a, commodo gravida, tincidunt sed, turpis. Aenean ornare viverra est. Maecenas lorem. Aenean euismod

- Cras gravida sem ut massa. Quisque accumsan porttitor dui. Sed

Talk to an expert and discover the perfect solution for your company

Fill out the form to send us your request

Contact us on Whatsapp

+39 345 15 33 446

Why choose us?